Driveshaft Manufacturing

At DCJ Inc, we prioritize quick-response ordering with the flexibility to accommodate custom changes tailored to your production needs. Our goal is to help you reduce inventory, improve cash flow, and enhance scheduling flexibility.

Quick-Response Ordering

Prioritizes fast ordering to meet urgent production needs.

Customizable Production Changes

Offers flexibility to adjust and tailor orders based on specific production requirements.

Agricultural Driveshafts

DCJ Inc is a proud distributor of Weasler® and Bare-Co products, offering aftermarket replacement drivelines to meet your agricultural needs. We also provide expert repair and replacement services for existing driveshafts.

Quality Components

DCJ Inc is a proud distributor of Weasler, Neapco and Bare-Co products.

Aftermarket Replacement Drivelines

We offer aftermarket replacement drivelines tailored to meet agricultural needs.

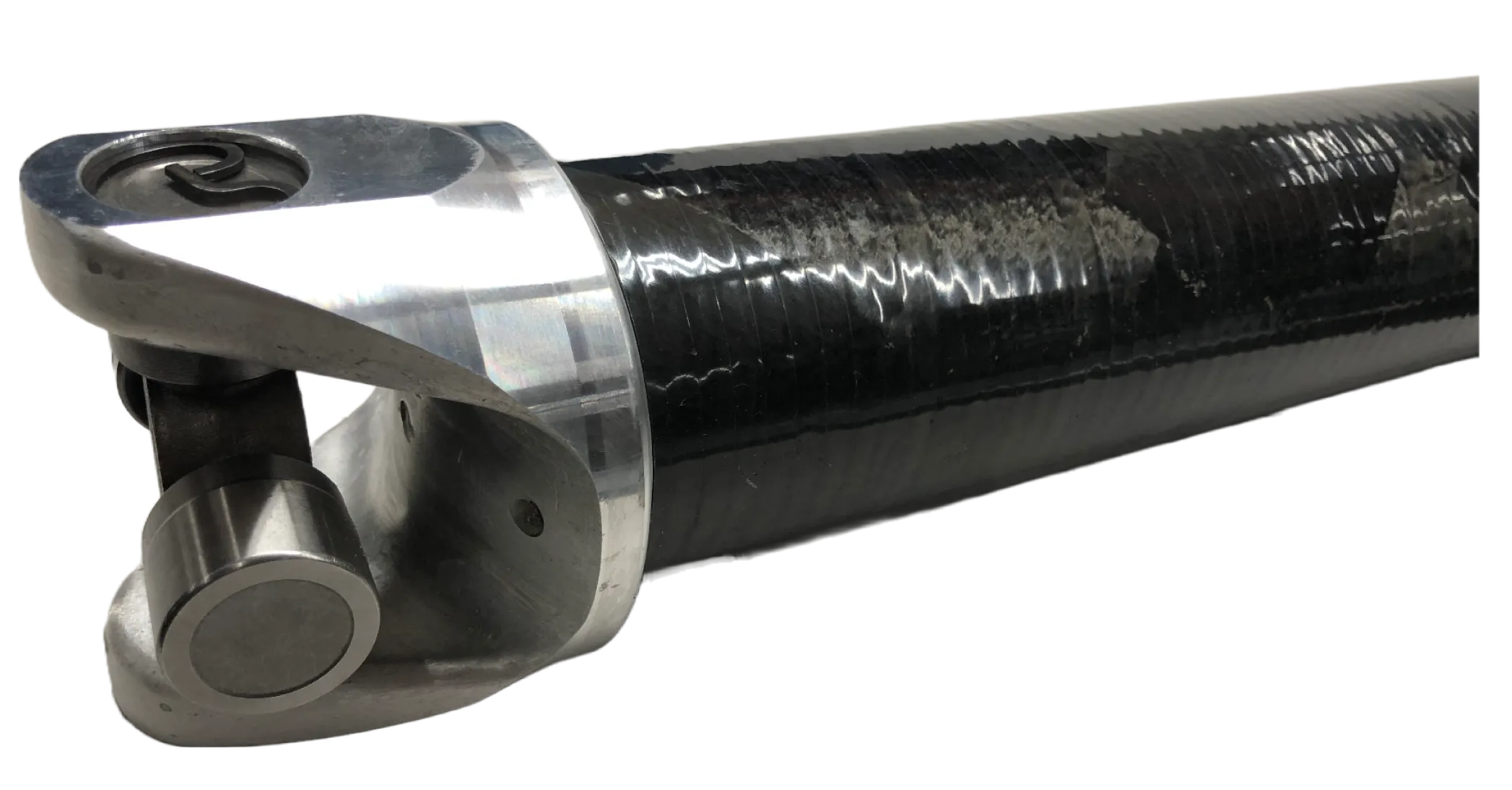

Carbon Fiber Driveshafts

DCJ Inc offers carbon fiber driveshafts for a wide range of applications. Our team is here to help you select the perfect shaft to meet your specific needs.

Reduced Mass

Nearly half the rotational mass of steel tubes, enhancing acceleration.

Higher Critical Speeds

Superior strength enables higher rotational speeds and supports longer driveshaft lengths and smaller

diameter design

Driveshafts Components

DCJ Inc offers a quick and convenient way to look up common universal joints, slip yokes, tube yokes, and tube shafts by series.

Quick Access

Fast and convenient lookup

Search by Series

lookup the right components by series

Balancing

An unbalanced driveshaft vibrates due to the centrifugal force generated as the heavier side rotates. To address this, a dynamic balancing machine spins the shaft while sensors detect points of imbalance through their specific sine frequency (essentially a sound wave).

Balancing involves attaching a counterweight opposite the heavier side to offset the imbalance. For safety, shafts are balanced at the lowest possible speed while ensuring alignment with the shaft's intended application. While perfect balance is unattainable, the goal is to reduce imbalance to acceptable tolerances, effectively eliminating vibration.

Repair & Modification

DCJ Inc. offers expert troubleshooting for your off-road and racing applications. Increased torque and horsepower often demand driveline upgrades, such as adjusting length, changing connections or series, or converting a two-piece steel driveshaft into a one-piece aluminum design.

Our skilled team evaluates your current assembly and provides fast, cost-effective solutions by reusing undamaged components or building a completely new assembly to meet your needs.

Failures & Vibrations

Explore common examples and issues to help you identify and diagnose driveshaft failures effectively.

How to Guides

Discover step-by-step guides on measuring a driveshaft and removing or installing new U-joints.