Heavy-Duty Cluthes

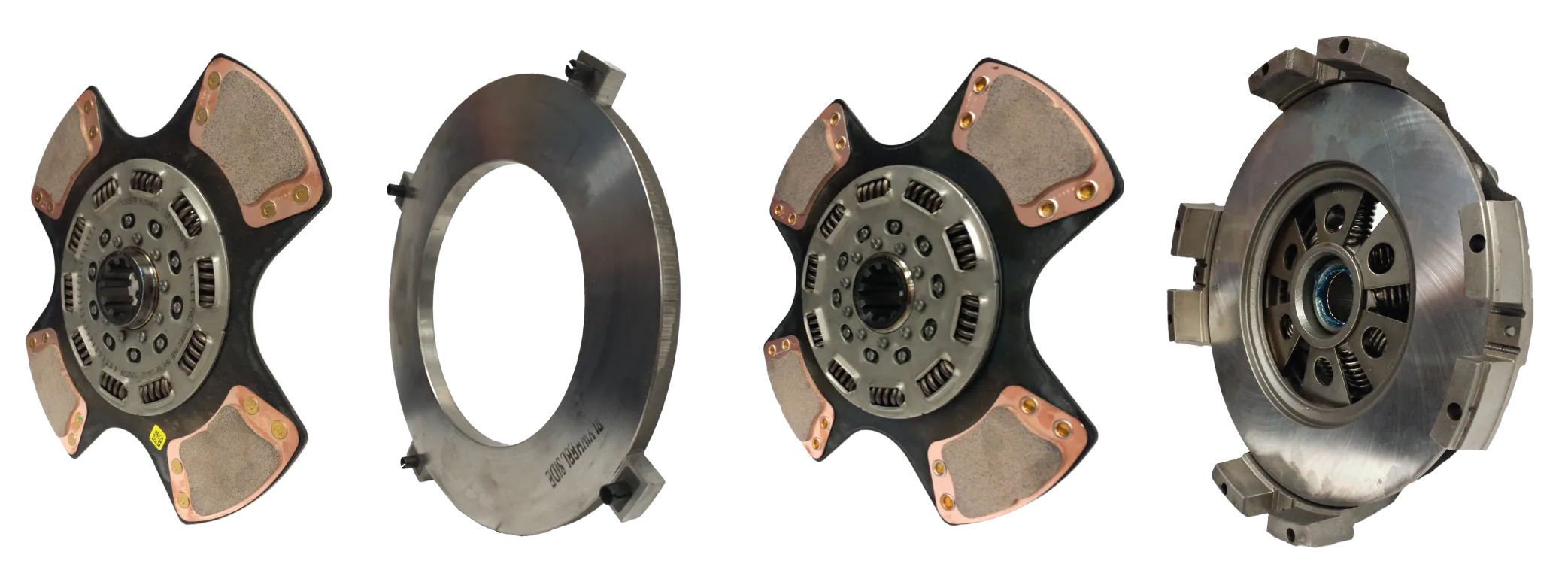

Heavy-duty clutches are designed for applications requiring high RPMs and high torque. Unlike personal vehicle clutches, which typically feature a single disc with organic facing material, heavy-duty clutches generally use two discs with ceramic button facings to deliver superior holding power and durability.

Over-Center Clutches

Over-center clutches, commonly referred to as power take-offs (PTOs), are used to transmit engine power through a driveshaft, sprocket, or sheave to secondary equipment. Typically housed in cast iron or similar durable materials, these clutches are integral to various applications, including crushers, rock chuckers, chippers, pump drives, construction and agricultural machinery, marine systems, and more.

Agricultural Clutches

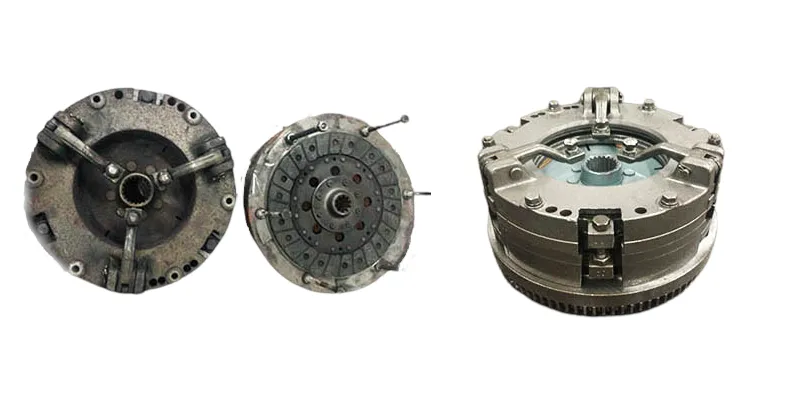

Agricultural clutches are engineered for low RPM applications requiring high torque. These clutches typically feature a two-plate system, consisting of a drive disc and a PTO disc. Commonly used in tractors, combines, sprayers, and other agricultural equipment, they are ideal for machinery that operates at lower speeds.

Vintage & Performance Clutches

For older vehicles, finding a replacement clutch can be challenging when the original fails. Over time, pressure springs may lose tension due to wear or corrosion, causing the clutch to slip as they struggle to maintain adequate pressure on the plate, disc, and flywheel. Oil and dirt contamination are also common issues. Rebuilding your vintage clutch is an excellent way to keep an older vehicle roadworthy and in show condition. Additionally, if you’re boosting horsepower in your classic car, upgrading clutch components may be necessary to handle the increased torque.

Clutch Failures

Explore common examples and issues to help you understand and diagnose clutch failures effectively.