Excessive Heat

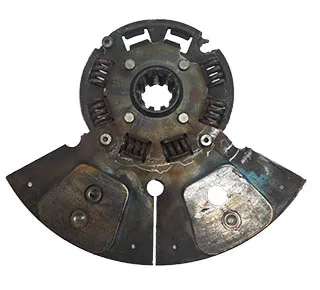

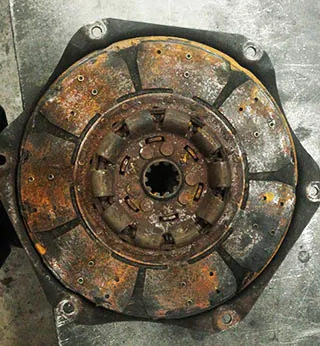

Pressure Plate Heat Damage

Excessive heat is the leading cause of clutch failure. When the temperature between the flywheel, discs, intermediate plate (floater plate), and pressure plate exceeds operating specifications, the friction material may wear away, and the metal components of the clutch can distort. This can lead to catastrophic clutch failure, posing significant risks to life, limb, and property.

Operator Errors

While excessive heat is the leading cause of clutch failure, improper vehicle operation is the primary driver of excessive heat. Actions that cause clutch slippage generate heat faster than it can dissipate, leading to premature wear and failure. Below are common operational errors that can initiate clutch failure:

- Riding the Clutch Pedal While in Motion:

This mimics the effects of a slipping clutch, applying continuous pressure on the release bearing and often causing it to fail. - Holding a Vehicle Stationary on an Incline with a Slipping Clutch:

Prolonged clutch slippage generates excessive heat and damages components. - Exceeding Load Specifications:

Overloading a vehicle can strain the clutch beyond its capacity, causing overheating and failure. - Starting in the Wrong Gear:

Initial movement in an incorrect gear creates unnecessary stress on the clutch. - Insufficient Acceleration Before Upshifting:

Failing to properly accelerate before shifting causes the engine speed and vehicle speed to differ significantly, leading to clutch overheating as it works to equalize speeds. - Skipping Gears While Upshifting:

Skipping gears increases the load on the clutch, exacerbating overheating and wear.

14" Pot Style Clutch

- Grooved Drive Pin Slots:

Incorrectly angled drive pins

Reuse of old drive pins

Failure to replace set screws - Worn or Fractured Drive Pins/Drive Slots:

Improper or non-installation of anti-rattle springs

Improper application

Improper maintenance (e.g., filing drive slots to fit angled drive pins) - Insufficient Clutch Release:

Incorrectly angled drive pins

Damaged drive pins

Improper or non-installation of anti-rattle springs

Damaged drive slots

Self-Adjusting Clutch

- Over-Adjusted Self-Adjusting Clutch:

Incorrect distance between the clutch brake and release bearing

Damaged self-adjusting cam tab

Improper maintenance - Excessive Bushing Wear/Failure:

Insufficient lubrication

Improper lubrication type

Bushing contamination

Damage to the transmission input shaft - Non-Adjusting Self-Adjusting Clutch:

Contaminants within the clutch housing - Worn Release Bearing Wear Pad:

Operating the vehicle without proper free play - Excessive Free Play:

Increased free play during the break-in period

Clutch brake not installed

Over-adjusted self-adjusting clutch

Improperly set linkage system

Common Operator Complaints

- Insufficient Clutch Release

Oil-contaminated disc

Incorrectly facing discs

Wrong disc installed

Warped disc

Clutch cover contamination

Missing or improperly tightened clutch cover mounting bolts

Release yoke bridge to cover contact upon full clutch release

Flywheel interference with the disc

Improper clutch cover-to-flywheel fit (Cover pinch)

Partial pressure plate retraction

Lever-to-pressure plate contact

Damaged pressure plate

Intermediate plate catching on improperly angled drive pins

Damaged intermediate plate

Absent clutch brake squeeze

Damaged clutch brake

Improper clutch brake use

Worn transmission drive gear spline

Transmission input drive gear contamination

Incorrect throw-out bearing installed

Throw-out bearing catching on the transmission stem

Damaged or incorrectly fitting pilot bearing

Bushing damage inside the release bearing sleeve

Release sleeve bushing-to-input shaft contact

Improper or non-installation of anti-rattle springs

Damaged or non-set positive separator pin

Improper clutch pedal height

Excessive free pedal

(15” flywheel) Step is greater than 0.002”

(Self-adjusting and SAS only) Incorrectly facing intermediate plate and spacer ring - Clutch Noise

Flywheel interference with the disc

Excessive flywheel run-out

Flywheel interference from the dampener spring cover

Clutch not firmly attached to the flywheel

Failing or improperly installed linkage system

Improper clutch adjustment via the linkage

Yoke bridge-to-cover contact

Release yoke fingers-to-cover contact

Input shaft not moving freely through the disc hubs (due to contamination or corrosion)

Excessive engine idle RPM

Uncovered transmission inspection hole

Damaged pilot bearing or release bearing

Insufficient release bearing lubrication

Worn release sleeve bushing

Damaged throw-out bearing

Retainer interference from the rear disc rivets

Wrong disc installed

Worn or fractured drive pins/drive slots

Incorrect ring rotation

Missing anti-rattle springs - Clutch Chatter

Disc grease or oil contamination

Excessive disc wear

Input shaft spline wear

Bound or worn linkage system

Excessive release yoke finger wear

Worn release bearing wear pads

Improperly set clutch engagement torque (for electronic engines) - Slipping Clutch

Operator errors leading to excessive heat

Lack of free pedal

Prolonged operation without free-play

Improper application

Vehicle overload

Disc grease or oil contamination

Improper clutch adjustment via the linkage

Damaged retainer assembly - Clutch Vibration

Improperly tightened clutch cover mounting bolts

Retainer assembly interference from the rear disc rivets

Improperly set free travel

Linkage system wear

Cross shaft wear

Disc worn down to the rivets

Free play changes due to excessive crankshaft end play

Loose or unbalanced flywheel

Improper seating of the clutch against the flywheel

Excessive flywheel run-out

Clutch Cover/Flywheel/Intermediate Plate/Pressure Plate

Clutch Cover to Yoke Fingers Contact

- Incorrect rotation of the ring

- Fractured release bearing housing

- Yoke finger breakage or excessive wear

- Clutch cover damage

- Incorrect clutch adjustment

- Improperly installed linkage system

- Linkage system breakage

Yoke Bridge to Cover Contact

- Over stroking the yoke to achieve correct clutch brake squeeze, which can result from:

Damaged or incorrect transmission bearing retainer capWorn yoke fingers and/or release bearing padsFractured or missing clutch brake - Incorrect yoke installation

- Improper linkage system setup

- Worn clutch brake

Fractured Clutch Cover

- Straightened release yoke fingers

- Incorrect torque applied to the flywheel mounting bolts

Release Lever to Pressure Plate Contact

- Incorrect release bearing travel

- Worn cross shaft bushings

- Worn cross shafts

Worn Release Lever

- Damaged throw-out bearing

- Improperly fitted throw-out bearing

- Worn or bound linkage

Clutch Cover/Flywheel Detachment

- Incorrect torque applied to the flywheel mounting bolts

Disc Related

Disc Grease/Oil Contamination

- Transmission leakage

- Rear main engine seal leakage

- Failure to remove rust preventative from the flywheel

- Greasing the input shaft splines

- Greasing the disc hub splines

Abnormal Disc Wear

- Unevenly worn or unsurfaced flywheel

Warped Disc

- Improper transmission installation

Flywheel Interfering With the Disc

- Disc rivets contacting the flywheel mounting bolts

- Disc installed in the incorrect direction

- Damaged pilot bearing

- Incorrect clutch installed

Burnt Disc

- Slippage

- Riding the clutch pedal

- Holding a vehicle stationary on an incline with a slipping clutch

- Prolonged operation without free play

- Incorrect clutch installed

- Excessive disc facing wear

- Partial clutch unloading caused by another component failure

- Retainer assembly interference

Damaged Damper Cover

- Forcing the transmission shaft into the disc hub

- Improper transmission installation

Damaged Disc Hub

- Torsional vibrations

- Shock load

- Improper transmission installation

- Incorrect disc installed

- Excessive flywheel run-out

Absent or Damaged Dampener Springs

- Shock load

- Torsional vibrations

- Improper application

- Excessive engine idle RPM

Damaged Disc

- Coasting with the clutch pedal depressed while the vehicle is in gear

Loss of Disc Friction Material

- Coasting with the clutch pedal depressed while the vehicle is in gear at high RPMs

Miscellaneous

Damaged Sleeve Bushing

- Input shaft not centered with the release bearing assembly sleeve during transmission installation

- Unsupported transmission in the sleeve bushing

Release Shaft Wear

- Damaged linkage system

- Variance in free play

- Improper clutch engagement

- Excessive side loading on the release bearing

Damaged Input Shaft Spline

- Torsional vibrations

- Misaligned input shaft

Damaged Input Shaft

- Undue release sleeve pressure on the input shaft

- Damaged linkage system

- Worn release bearing

- Worn release yoke fingers

- Push-starting the truck

- High-speed downshift

Release Sleeve Bushing to Transmission Input Shaft Contact

- Protruding cross shafts through the release yoke

- Damaged release yoke fingers

- Improper clutch cover installation

- Improper fit of the clutch cover into the flywheel pilot

- Misaligned transmission bell housing with the engine housing

- Loose transmission mounting bolts

- Improper linkage system adjustment

Worn Release Yoke Fingers

- Riding the clutch pedal while in motion

- Operating the vehicle without free play

Damaged Retainer Assembly

- Improper transmission installation

- Rivet contact from a worn disc

- Improper clutch adjustment via the linkage

Damaged Positive Separator Pin

- Improper installation

Damaged Kwik-Adjust® System

- Failure to fully depress the adjuster while rotating the gear

- Rotating the gear while the clutch is engaged

Damaged Throw-Out Bearing

- Prolonged partial clutch release while in motion

- Prolonged operation without free play

- Continuous contact with the release levers

Damaged Pilot Bearing

- Insufficient lubrication

- Improper outer bearing race fit in the flywheel

- Improper inner bearing race fit on the input shaft

Release Bearing Failure

- Inadequate lubrication

- Incorrect lubricant

- Prolonged partial clutch release while in motion

- Excessive wear on wear pads and yoke fingers

Excessive Clutch Brake Wear

- Insufficient clutch release

- Engaging the clutch brake while the vehicle is moving and the transmission is in gear

- Improper installation

- Damaged transmission bearing cap

- Clutch brake exceeding its normal life expectancy