Driveshaft Vibrations

Driveshaft vibrations typically fall into four main categories

- Caused by an unbalanced driveshaft.

- Occur once per driveshaft revolution.

- Common causes include shaft damage, missing balance weights, or foreign material stuck to the driveshaft.

Transverse Vibrations:

- Occur twice per driveshaft revolution.

- Often result from excessive U-joint angles or a shaft that is out of phase with its design specifications.

- A yoke misaligned by just one spline can lead to torsional vibration issues.

Torsional Vibrations:

- Happens when a driveshaft operates at an RPM exceeding the safe limits dictated by its length, diameter, and mass.

Critical Speed Vibrations:

- Vibrations caused by failing components such as U-joints or motor and transmission mounts

Example: A failing U-joint can create significant vibration.

Component Failure:

Driveline Failures

- A sudden force applied to a driveline component, making it the most common cause of failure.

- Cold temperatures can exacerbate shock load failures.

- Common scenarios include:

Driving into an immovable object under power.

Tires suddenly gaining traction after spinning on a slick surface.

Attempting to pull an immovable load, such as a trailer with frozen brakes.

Popping the clutch at higher-than-normal RPMs.

Shock Load:

- Prolonged force applied beyond recommended specifications.

- Typically caused by pulling loads heavier than the vehicle’s rating.

Excessive Torque Load (Torsional Fatigue):

- Occurs when driveline components are not suited to the vehicle’s specifications or intended purpose.

Improper Application:

- A general term for damage on the load-bearing surfaces of driveline components, which can include:

Brinelling: Permanent indentations on the surface.

Spalling: Flaking or cracking of surface material.

Galling: Material transfer or tearing due to friction.

Surface Fatigue (Contact Fatigue):

- The RPM at which a driveshaft operates beyond safe limits relative to its length, diameter, and mass, leading to instability and potential failure.

Critical Speed:

- Shock Load:

Sudden force applied to the driveline. - Excessive Torque Load:

Prolonged force exceeding recommended specifications. - Improper Application:

Using driveline components not suited for the vehicle or its intended purpose.

Spalling, a form of surface fatigue, occurs when the bearings inside the U-joint bearing cap fail to move freely. This results in the bearings grinding against the cross, creating grooves on the surface.

- Water or Dirt Contamination:

Infiltration of foreign materials into the bearing assembly. - Improper Lubrication Type:

Use of unsuitable lubricants for the application. - Lubrication Failure:

Insufficient or degraded lubrication. - Excessive Load:

Prolonged exposure to loads beyond the recommended limits. - Operation Beyond Maximum Mileage:

Usage exceeding the specified service life of the components.

Brinelling occurs when the bearings inside the bearing cap imprint onto the outer surfaces of the U-joint cross.

- Continuous Excessive Torque Loads:

Prolonged force beyond recommended limits. - Seized Slip Yoke Splines:

Preventing the shaft from adjusting in length. - Excessive U-Joint Operating Angles:

Operating at angles greater than recommended. - Improper Application:

Using components unsuited for the vehicle or purpose. - Sprung or Damaged Yoke:

Compromising proper operation. - Improper or Insufficient Lubrication:

Failing to provide adequate lubrication for smooth operation.

The factors that cause brinelling and spalling can escalate to severe damage, resulting in a burned-out U-joint cross.

- Lack of Lubrication:

Insufficient lubrication leading to excessive friction and heat. - Improper Maintenance:

Failure to follow recommended servicing practices. - Incorrect Lubrication Type:

Using a lubricant unsuitable for the application. - Improper Application:

Employing components that are not designed for the specific use case.

- Excessive Torque Loads:

Prolonged force beyond recommended specifications. - Shock Load:

Sudden, intense force impacting the driveline. - Improper Application:

Using components unsuitable for the vehicle or its intended use. - U-Joint Failure:

Malfunctioning U-joints causing additional stress. - Improper Installation:

Incorrect setup leading to compromised performance.

- Improper Bearing Retainer Bolt Torque:

Incorrectly tightened bolts leading to stress and failure. - Improper Installation:

Incorrect assembly compromising component integrity. - Re-Use of the Bearing Strap:

Using worn or previously stressed straps instead of replacing them.

- Shock Load:

Sudden force causing stress at the weld joint. - Improper Welding Procedure:

Inadequate technique or materials leading to weak welds. - Balance Weights Positioned Near the Weld:

Improper placement increasing stress at the weld. - Excessive Vibration:

Persistent vibrations weakening the weld over time.

End galling, or galling, is a form of surface fatigue marked by marring or damage on the flat surface at the end of the U-joint cross.

- Excessive U-Joint Operating Angles:

Operating beyond recommended specifications. - Improper Assembly:

Incorrect installation leading to stress on the components. - Sprung or Damaged Yoke:

Compromised yoke integrity causing misalignment. - Lack of Lubrication:

Insufficient lubrication resulting in friction and surface wear.

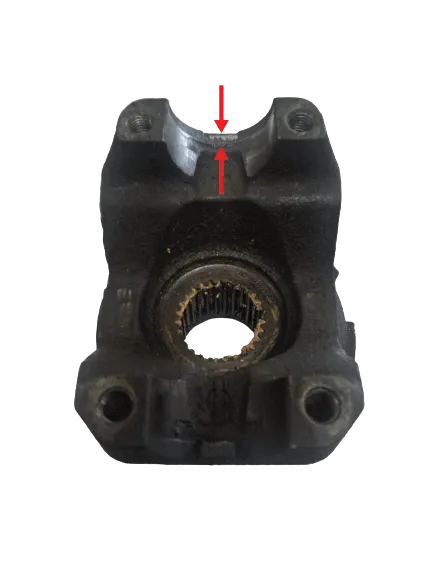

A sprung yoke, with a bend occurring within the yoke's ears, may appear imperceptible at a glance and is often detected only during U-joint replacement. In such cases, the crosses will not align properly with the holes on both sides of the yoke.

- Excessive Torque Loads:

Forces exceeding the yoke's design specifications. - Improper Application:

Using the yoke in conditions outside its intended purpose. - Incorrect U-Joint Removal:

Mishandling during removal, causing damage to the yoke. - Improper Operating Angles:

Operating beyond recommended angles, leading to stress. - Thrown Driveshaft:

Sudden ejection of the driveshaft causing physical damage. - Improper Installation:

Incorrect assembly leading to misalignment or stress. - Poor Maintenance:

Neglecting regular maintenance, contributing to wear and damage.

- Shock Load:

Sudden, intense force causing stress and breakage. - Excessive Torque:

Forces exceeding the spline's design limits. - Improper Application:

Using the spline in unsuitable conditions or beyond its intended purpose.

Additional Resources