Standard Push Pull Cables

Our full range of push-pull controls provides reliable linear motion transmission from one location to another, offering both ease of installation and superior performance.

Features:

- Constructed with durable materials and long-lasting seals for environmental protection.

- Withstands extreme temperatures ranging from -65°F to 230°F.

Applications:

- Implement and throttle control

- PTO/4WD and valve activation

- Remote battery and electrical disconnect

- Transmission shifting

- Hydrostatic drives and latches

Blue Max™ Push Pull Cables

The Blue Max™ motion control cable line is engineered for high-performance push-pull applications. Designed with aviation engineering principles, these cables deliver extreme low friction, minimal motion loss, and an unparalleled smooth feel—making them the industry leader in performance.

Key Features:

- Exceptional for long runs with complex cable routing and highly efficient for shorter runs.

- True 4-inch minimum bend radius for versatile installation.

- Lubed for life with a binder-wired PTFE core conduit.

- Durable outer jacket resistant to abrasions, gasoline, diesel, and chemicals.

If control issues have you frustrated, switch to the Blue Max™ high-performance cable line for superior results.

Available exclusively with 10-32 and M5 end rods.

How To Order Custom Cables

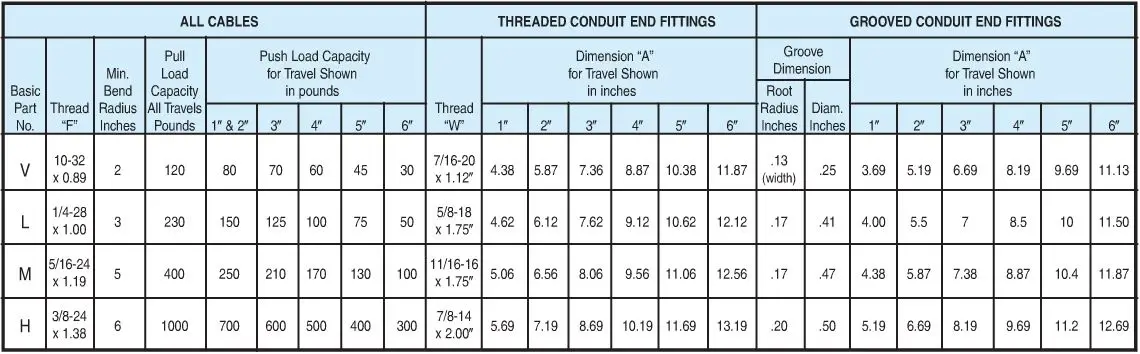

A - Duty (Load capacities & length of travel)

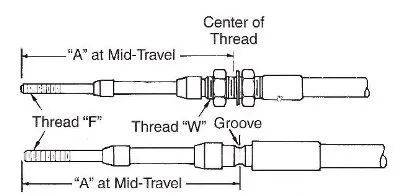

B - Conduit End Fittings

- Type T: Threaded conduit end fitting designed for bulkhead mounting.

- Type G: Grooved conduit end fitting suitable for mounting with U-bolts or clamps.

C - Overall Length & Travel

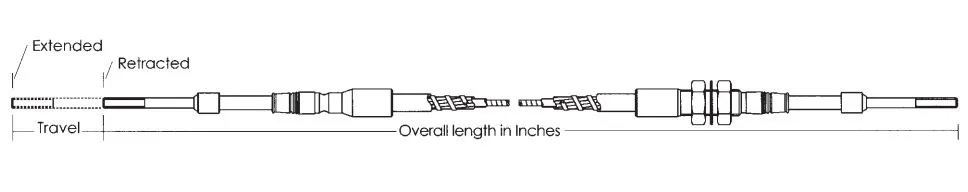

For Replacement Cables:

- Remove the old cable.

- Measure the overall length as shown in the diagram below.

- Measure the travel length (1" to 6"). Note: 7" and 8" travel options are available for select sizes.

- Determine the thread size ("F") and select the appropriate basic part number from the table above.

For New Cables:

- Determine the required overall length.

- Measure the required travel. Add 1/4" to this measurement, then round up to the nearest whole inch.

- Assess load requirements and select the appropriate basic part number from the table above.