Driveshaft Manufacturing

At DCJ, we focus on quick response ordering with the potential for custom changes available to meet your production requirements. Our goal is to reduce your inventory, improve your cash flow and optimize your scheduling flexibility.

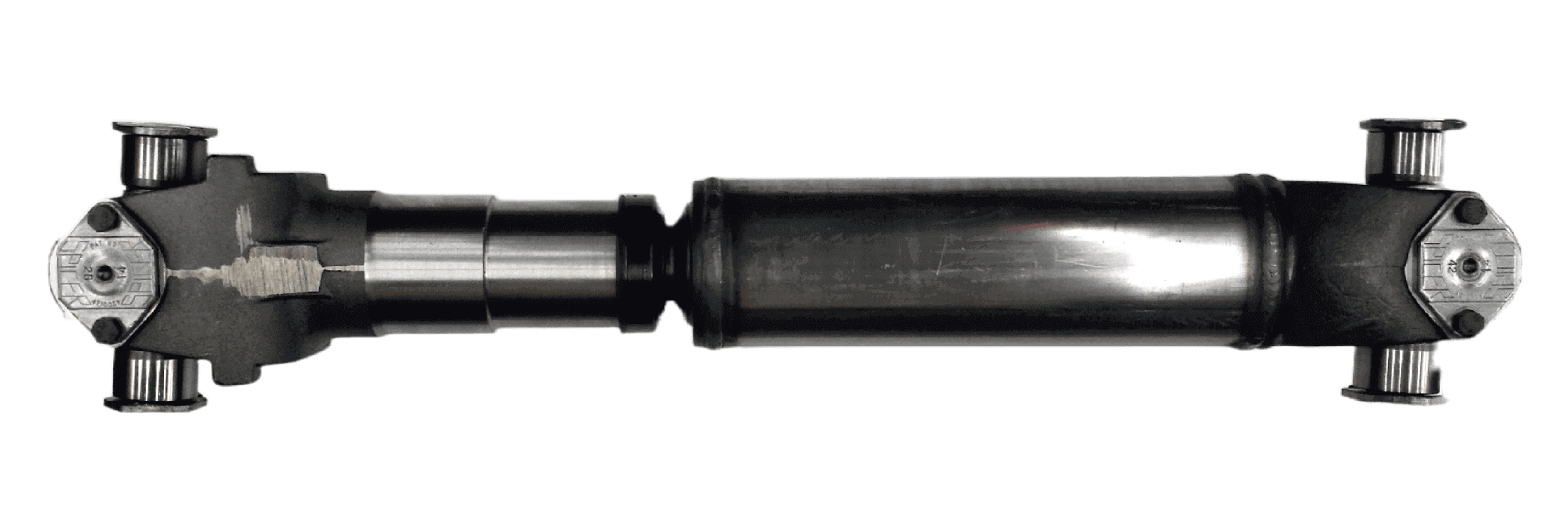

Agricultural Driveshafts

DCJ is a Weasler® Distributor. We provide aftermarket replacement drivelines for your agricultural needs. We can also repair or replace your existing driveshaft as needed.

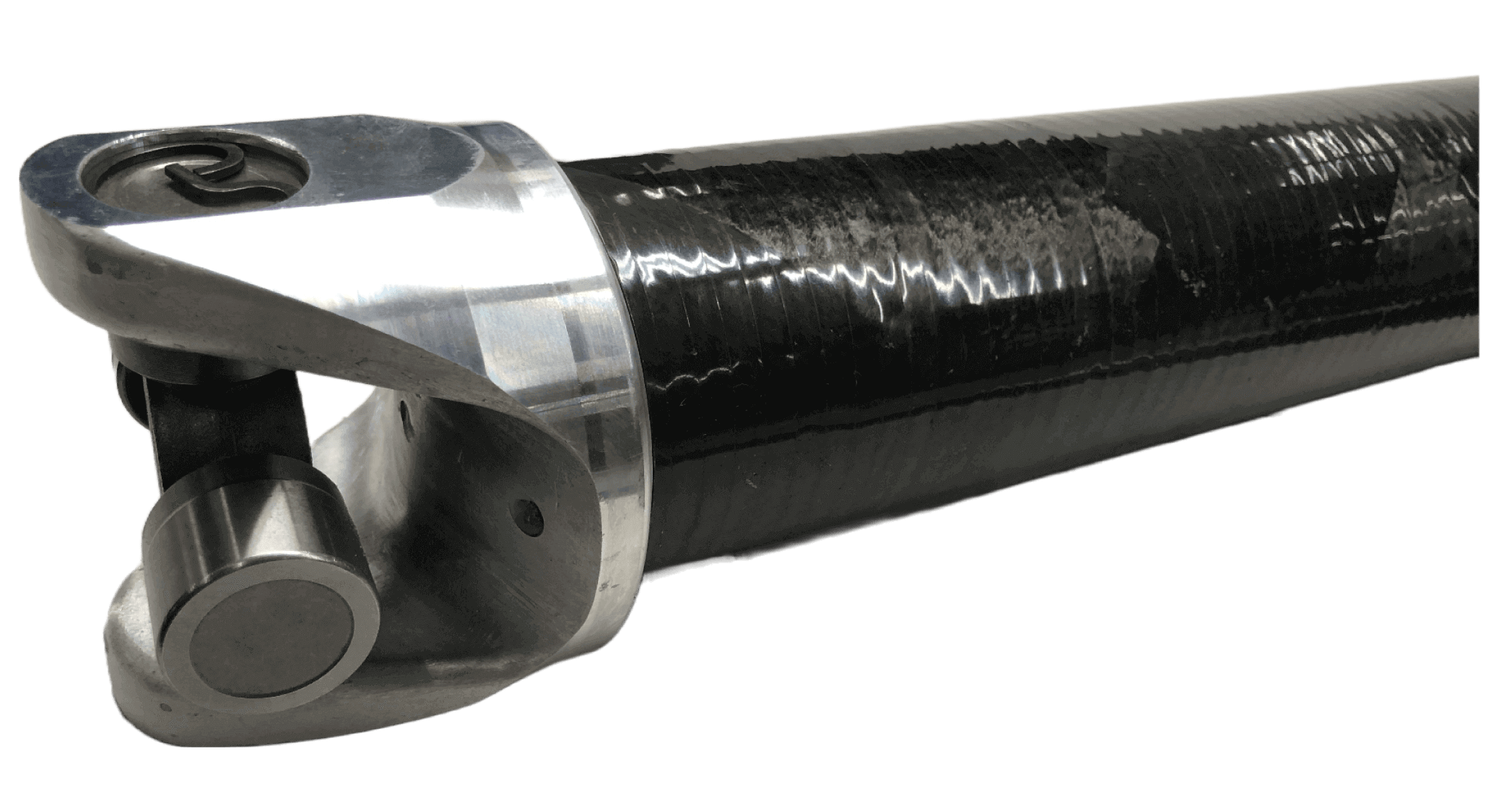

Carbon Fiber Driveshafts

DCJ offers carbon fiber driveshafts for a variety of applications. We can assist you in determining the correct shaft for your application.

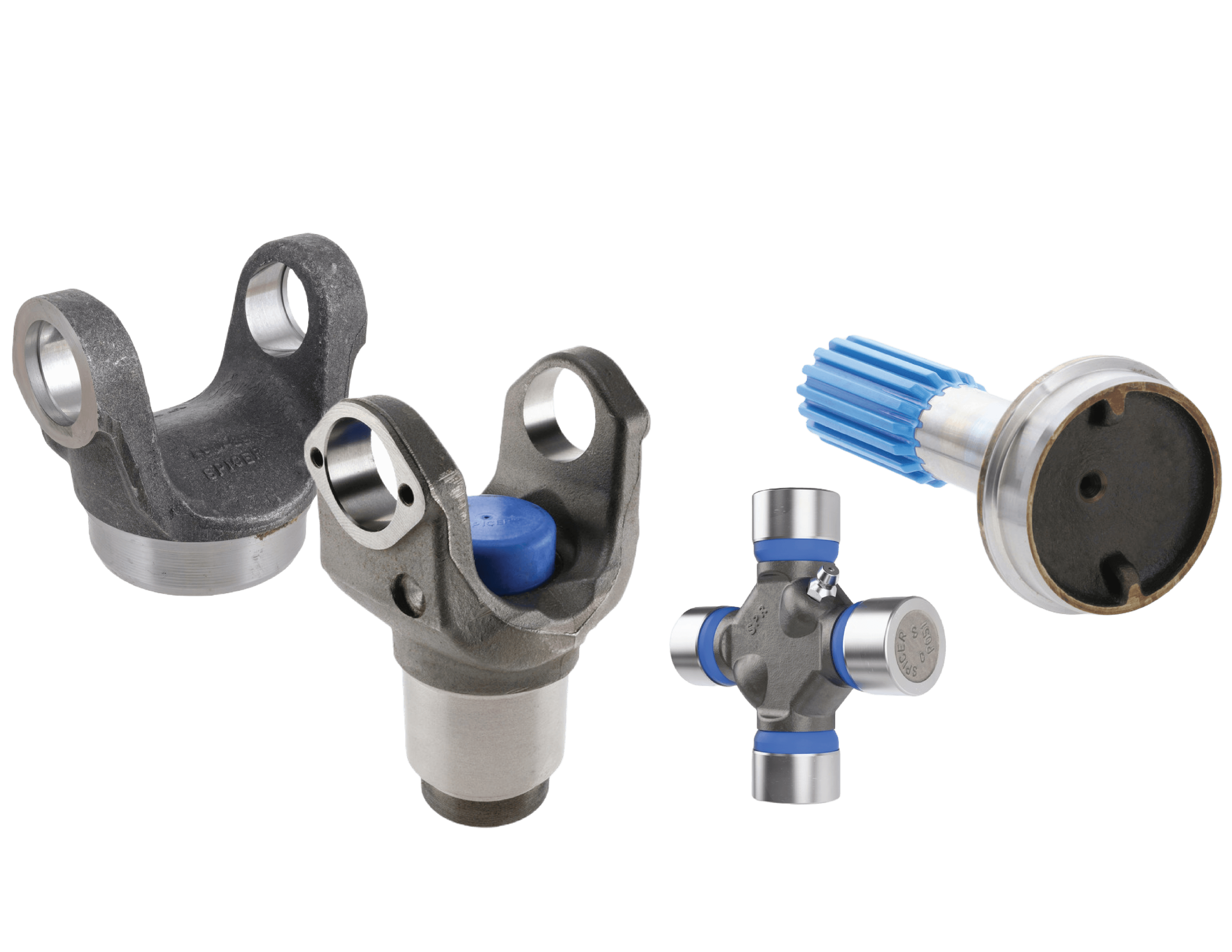

Common Driveshaft Components

DCJ provide a quick and easy way to lookup common universal joints, slip yokes, tube yokes & tube shafts by series.

Driveshaft Repair & Modification

DCj can assist in trouble shooting your off-road and racing applications. Modifications and increased torque/horsepower require upgrades to your existing driveline. This includes modifying length, connections/series or converting a two piece steel driveshaft to a one piece aluminum driveshaft. Our team of dedicated professionals will evaluate your existing assembly and provide a fast response at an economical cost by reusing any undamaged components or build an entirely new assembly.

You can find information on common driveshaft failures and vibrations below.

Driveshaft Balancing

A driveshaft in a state of unbalance will vibrate as an indirect effect of the centrifugal force created as the heavier side of the shaft makes a revolution. A dynamic balancing machine is used to rotate the shaft and sensors detect the points of unbalance by its specific sine frequency (basically a sound wave). An unbalanced driveshaft is then balanced by attaching a counterweight opposite from the heavier side. A shaft is balanced as slow as possible for safety purposes, but as fast as necessary for its intended application. A perfectly true balance is not possible. Therefore, reducing an unbalance to acceptable tolerances to negate vibration is the goal.

Driveline Failures & Vibrations

Common examples and issues to help you learn and diagnose driveshaft failures.