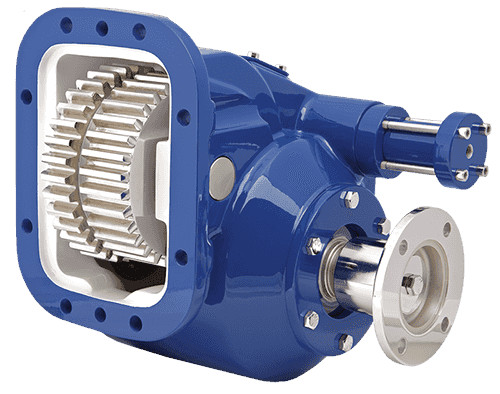

New PTO

Choosing the right PTO for your wet line system will not only ensure you get the most out of your system but will also save you money in expensive repairs and downtime.

What we will need to help you build your PTO.

- Transmission and model – It is important to know your transmission and model so we can pair a PTO that will not cause damage to your system.

- Position – Your transmission may have a specific aperture to accept a PTO. Know which side the PTO will be mounting to is important for the function of your system.

- Rotation direction – The direction of rotation in your PTO will influence the rotation of other components in your system. Knowing the proper rotation will save you time and money.

- Mounting face – If the driven component is directly coupled to the PTO, what are the mounting surface requirements and what are the dimensions of the shaft for the PTO?

- Engagement – Constant drive, mechanical and clutch shift are the different types of engagement your PTO may have. Constant drive PTOs are ideal for continuous duty applications. While mechanical and clutch shift PTOs are often used in systems where intermittent use is common.

Two of the most important items to determining the right PTO for your needs are horsepower (HP) and torque (T).

How to calculate horsepower? (Pump efficiency is typically expressed as a percentage)

HP = GPM x PSI ÷ 1714 ÷ Pump Efficiency

How to calculate torque load?

T = HP x 5252 ÷ RPM

Refer to Muncie's What Do You Need To Know To Specify A PTO for more information

PTO Rebuild

Our team can rebuild your existing PTO. We know that when a PTO fails it is typically a gasket issue. As long as the case is not damaged, we can typically repair gears, gaskets, seals, shift linkages, etc.